MABI Robotic's MAX Series - Innovation in High-Precision Milling

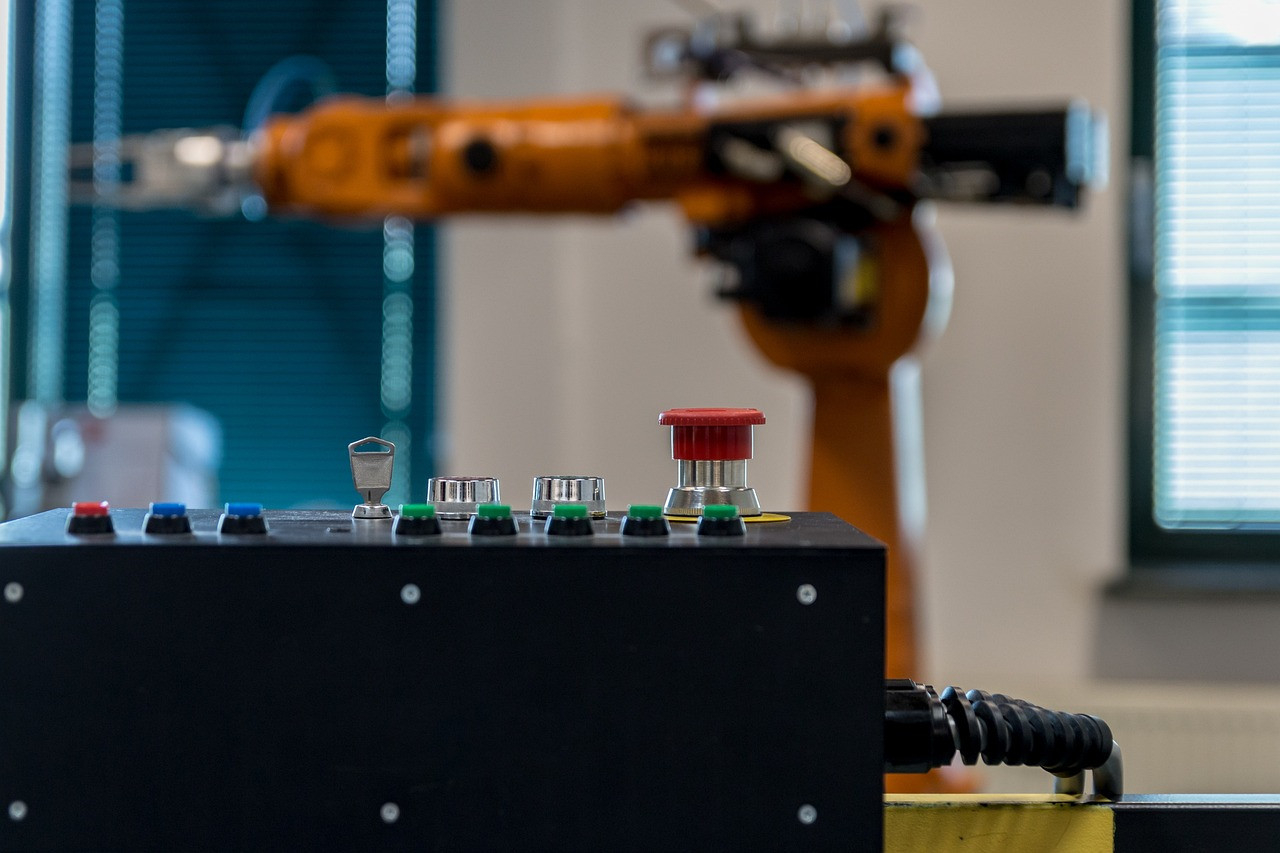

MABI Robotic's robots stand out in the competitive market due to their integration of secondary encoders on all axes. This advanced technology ensures unparalleled precision by allowing the robotic arm to make minute adjustments in real-time. Secondary encoders measure the actual position of the robot’s components, significantly improving accuracy over traditional systems. This makes them ideal for both additive (3D printing) and subtractive (milling) CNC applications, where small deviations can lead to costly errors.

The company's MAX series robots are particularly noteworthy. For example, the MAX-100-2.25-P robotic arm, the smallest in the MAX lineup, offers exceptional performance. With a payload of 100 kg and a reach of 2.24 meters, this robot delivers impressive capabilities for precise manufacturing tasks. As businesses seek more reliable and precise robots, the MAX series meets these demands with consistently high standards.

Continuous Innovation for a Competitive Edge

MABI Robotic continuously evolves its product line based on customer feedback and industry needs. The upcoming MAX-200-2.5-P robotic arm is a testament to this commitment to innovation. Scheduled for release in late 2024, this new model promises to further enhance the company’s reputation for precision and durability, catering to heavy-duty industrial applications with even higher demands.

Robotic arms equipped with secondary encoders, such as those from MABI Robotic, are setting new benchmarks in the manufacturing industry. Their unmatched precision and reliability make them indispensable tools for companies striving to achieve excellence in their production processes.